ROAOCAT®205- 增加体系操作宽容度催化剂

ROAOCAT®205-Increase Processing Latitude Catalyst

优点Advantages

·ROAOCAT®205 催化剂是为“高二氯甲烷配方”(含量>20)开发的胺催化剂。它适用于低密度(密度少于10kg/m2)的大块泡沫的额生产

ROAOCAT®205 amine catalyst is designed for MC rich(MC>20parts)flexible slab foam. It can be used to produce density below 10kg/m2 flexible slab foam

·ROAOCAT®205 催化剂催化能力较强,具有较高的催化活性。使用中,泡沫的表面固化速度(表干效果)快

ROAOCAT®205 catalyst has strong catalytic ability and high activity .It has fast surface curing when it is used

·与传统液胺催化剂相比,在发泡过程中,ROAOCAT®205 催化剂能提供更加优异的操作宽容度和稳泡效果,同时增加泡沫手感硬度

ROAOCAT®205 catalyst can provide wide processing latitude, excellent foam stability in foaming compared with traditional amine catalyst

·与同类催化剂相比,ROAOCAT®205催化剂能增加泡沫手感硬度

Hardness improvement compared with the same grade amine

典型特性Typical Properties

|

粘度Viscosity

|

25℃.cPs

|

99.8

|

|

密度Density

|

25℃,g/ml

|

0.993

|

|

水溶性Solubility

|

完全溶解Completely Soluble

|

配方Formulation

|

Polyol

|

100

|

|

|

ROAOCAT®CS9193

|

4.5

|

|

Amine

|

0.45

|

|

ROAOCAT®D19

|

varied

|

|

Water

|

8

|

|

MC

|

40

|

|

TDI Index

|

120

|

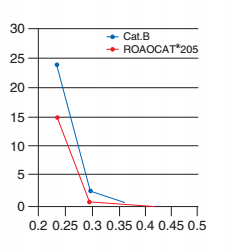

在7 密度减少锡催化剂用量时,与催化剂B 相比,ROAOCAT®205催化剂的泡沫更稳定。

In 7kg/m3 Foam, ROAOCAT®205 catalyst's foam is more stable than that of Cat. B when tin decreased.

|